How long to keep christys red hot blue glue before water?

Are you tired of your DIY projects falling apart because you don’t know how long to let the glue dry? Specifically, Christy’s red hot blue glue – how long should you wait before exposing it to water?

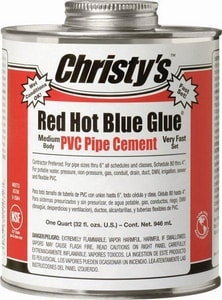

Christy’s red hot blue glue is a popular adhesive for plumbing and other DIY projects. However, it can be confusing to know how long to let it dry before using the item or exposing it to water. Using the glue too soon can cause it to weaken and not hold up over time.

Knowing how long to let Christy’s red hot blue glue dry before exposing it to water is crucial for the success of your DIY projects. In this article, we will discuss the factors that affect drying time and provide tips to ensure your projects are strong and long-lasting.

What is Christy’s Red Hot Blue Glue

Christy’s Red Hot Blue Glue is a premium formulation solvent cement that is designed to be used with PVC pipe and fittings. It is ideal for use in potable water applications and is able to provide an exceptional joint strength that is able to withstand even the most demanding conditions.

One of the key features of Christy’s Red Hot Blue Glue is its ability to provide a secure joint in a short amount of time. Unlike other solvent cements, this formula has a fast cure time, which means that the glue sets quickly and allows for maximum productivity.

When applying Christy’s Red Hot Blue Glue, it is important to ensure that the pipe and fitting are clean and dry. This can be achieved by wiping them down with a dry cloth prior to application. The glue should be applied in a coat that is thick enough to cover the entire area where the pipe will go into the fitting, but not so thick that it drips or runs.

After the glue has been applied, the pipe should be inserted into the fitting until it bottoms out. It is important to make sure that the pipe is square and that it has an interference fit. This will help to ensure that the joint is both strong and leak-free.

Christy’s Red Hot Blue Glue is also quite versatile and can be used for a variety of different applications. It is capable of bonding PVC pipe and fittings of all sizes, including flexible PVC pipe. In addition, it can also be used for joining pieces of ABS pipe in sizes ranging from 1½” to 8″.

Purpose of Glue

Glue is a common adhesive used in a variety of industries including construction, woodworking, and craft-making. The purpose of glue is to bond two materials together, creating a strong, lasting connection. There are many different types of glue available on the market, each specifically designed for different materials and applications.

One of the key benefits of using glue is its ability to bond materials together without the need for additional hardware, such as nails or screws. This results in a cleaner, more streamlined appearance, and can also save time and money in construction or DIY projects.

In addition to its bonding properties, glue also plays an important role in filling gaps between materials. For example, when installing wooden floorboards, there may be small gaps between the boards. Using glue to fill these gaps provides a more stable and secure surface, preventing the boards from shifting or creaking over time.

Some types of glue also offer additional benefits, such as water resistance, flexibility, and fast drying times. For example, glue designed for use in humid or damp conditions will offer a stronger bond than standard glue, which can weaken or break down over time due to exposure to moisture.

When selecting a glue for your project, it is important to consider the materials being used as well as the application. Some glues work better on certain types of materials than others, and some may be better suited for small or intricate projects while others may be better for larger construction jobs.

Overall, the purpose of glue is to provide a strong, lasting bond between materials while filling gaps and providing additional benefits such as water resistance or flexibility. With so many different types of glue available, it is important to choose the right one for your project to ensure a successful and long-lasting result.

Prerequisites for Using the Glue

Before using any type of glue, there are certain prerequisites that must be met in order to ensure a successful bond between materials. These prerequisites can vary depending on the type of glue being used and the materials being bonded, but there are some general guidelines that apply to most types of glue.

Firstly, it is important to make sure that the surfaces to be bonded are clean and free of debris. Any dirt, dust, or other contaminants can interfere with the bonding process and weaken the bond over time. To clean the surfaces, use a dry or damp cloth to wipe away any debris and allow the surfaces to air dry completely before applying the glue.

Secondly, it is essential to make sure that the surfaces are properly prepared to receive the glue. This may involve roughening or sanding the surfaces to create a stronger bond, or using a primer or bonding agent to help the glue adhere more effectively. It is important to follow the manufacturer’s instructions carefully when using these types of products to ensure proper application and maximum bond strength.

Another important prerequisite for using glue is ensuring that the materials being bonded are compatible with the type of glue being used. Some glues may not work effectively on certain types of materials, or may even damage them. It is important to check the manufacturer’s recommendations for the glue and ensure that it is appropriate for the materials being bonded.

Lastly, it is important to ensure that the environment in which the glue is being used is appropriate for the type of glue and the materials being bonded. For example, some types of glue may be affected by cold or humid conditions, while others may require a certain temperature or humidity level for optimal performance. It is important to read the manufacturer’s instructions carefully and follow any recommended environmental conditions for the glue.

By following these prerequisites, you can help to ensure that your glue bonds are strong, effective, and long-lasting. Whether you are working on a small DIY project or a large construction job, taking the time to properly prepare your surfaces and materials before using glue can make all the difference in the success of your project.

Instructions on How Long to Keep Christy’s Red Hot Blue Glue Before Water

Christy’s Red Hot Blue Glue is a premium formulation solvent cement designed for use in joining PVC pipe and fittings. It is a fast-drying and high-strength adhesive that provides an exceptional bond. However, it is important to allow sufficient time for the glue to cure before exposing the joint to water. Here are the instructions on how long to keep Christy’s Red Hot Blue Glue before water:

It is recommended to wait at least 15 minutes before pressurizing the system or adding water to allow the glue to cure properly. The joint should be held firm for a few seconds after assembly to ensure optimal sealing and prevent any wobbling or loosening. For larger pipe diameters, up to 8 inches, it may be necessary to extend the curing time for up to one hour.

In humid or damp conditions, you may need to allow additional time for the glue to dry and cure. Similarly, if the temperature is lower than 50°F, it may take longer for the glue to cure, and it is recommended to allow a full 24-hour wait time before adding water.

To ensure the strongest bond and maximum joint strength, make sure that the pipe is inserted fully into the fitting until the pipe bottoms out in the socket. Also, make sure that the pipe is square and clean, and that you apply an even, medium coat of the cement to both the pipe surface and the fitting socket.

A correctly sized applicator is recommended for maximum productivity and minimum wasted cement. It is important to use an active solvent cement formulation that includes the preferred solvent for your specific type of PVC pipe. For flexible PVC pipe or flex-vinyl applications, Christy’s Red Hot Blue Glue is not recommended.

In case you encounter any drippy pipe or excess cement at the joint, we advise wiping it off with a dry cloth and allowing a little trial dry time before installing the joint. To achieve an accurate diameter interference fit, it is recommended to re-run all that pipe with a new coat of cement.

Meet Lila Robinson, an expert in the world of plumbing with a talent for delivering valuable insights and captivating articles on an array of plumbing topics. With years of experience handling complicated plumbing issues, Lila has become a go-to resource for homeowners and businesses alike.

Packing vast knowledge in plumbing tools and science, Lila creates a sense of community on her blog and social media accounts, engaging with readers from all walks of life. Her writing style is authentic, unique, and engaging, and she has an exceptional ability to break complex concepts into understandable ideas.

If you have encountered a plumbing issue, chances are Lila Robinson has conquered it. Her articles uncover the underlying problems behind some of the most unexpected plumbing problems, from tankless water heater error codes to drain snakes in vents.

Whether you’re a beginner or an experienced plumber, Lila Robinson’s blog has something for you. Follow her social media accounts to keep up-to-date with the latest posts and join the conversation.